Product Introduction:

TYPES MJS, MJSS, MJCLS, and MJCLSS

Quick,convenient assembly using sandard rools;High push out & torque-out resistance;

Distortion-free installation;Reverse side remains flush.

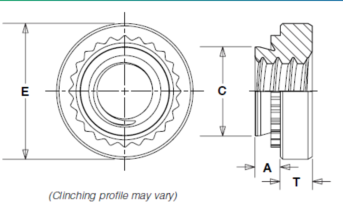

Self-clinching nuts are installed by placing them in properly sized holes in sheets and applying a parallel squeezing force to the head of the nut. The sheet metal surrounding the head cold flows into an undercut thereby making the fastener an integral part of the sheet. A serrated clinching ring prevents the fastener from rotating after installation.

Provide load-bearing threads in thin sheets with high pushout and torque-out resistance.

PRODUCT DESCRIPTION

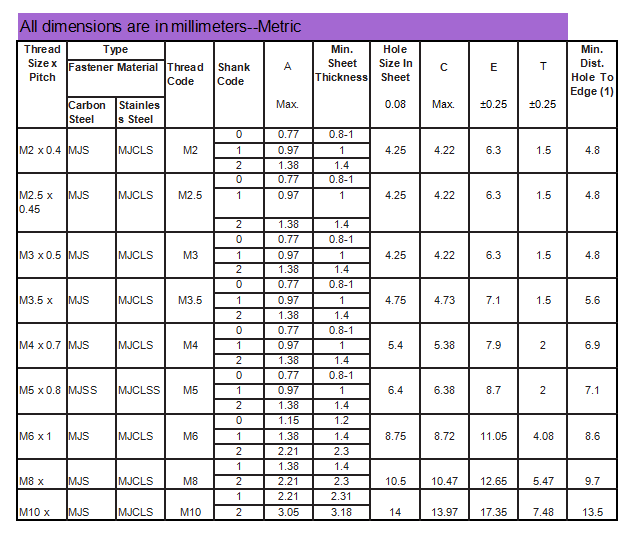

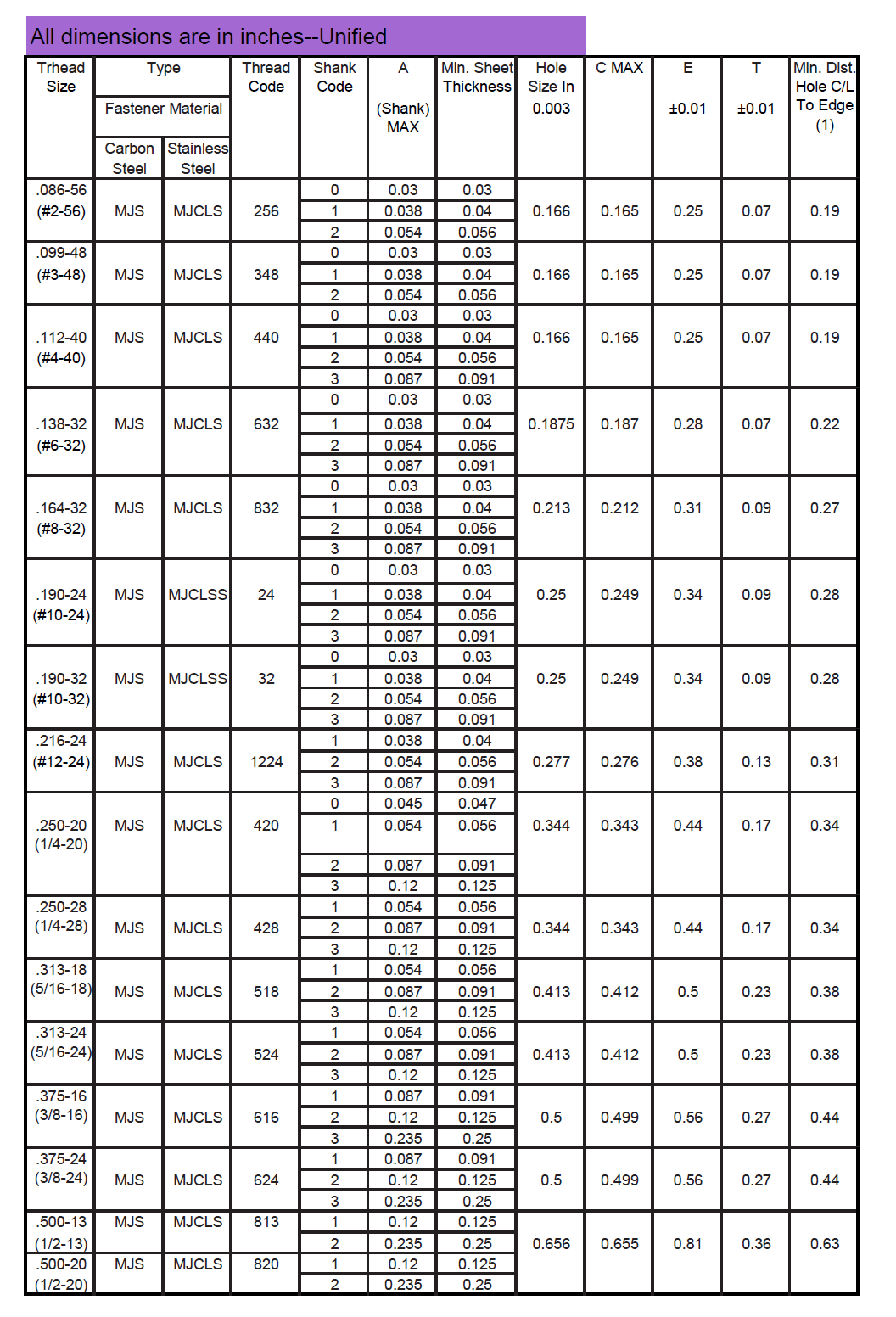

Types MJCLS / MJCLSS are recommended for use in steel or aluminum sheets HRB (Rockwell "B" scale) 70 or less and HB (Hardness Brinell) 125 or less.

Types MJS / MJSS are recommended for use in steel or aluminum sheets HRB (Rockwell "B" scale) 80 or less and HB (Hardness Brinell) 150 or less.

Common mistakes in fasteners choosing,how many items do point you?

Nov 08, 2018

Employee Routine safety production audit and training by Local Government

Oct 22, 2018

Which Processes Can Replace Hard Chrome Plating

Sep 21, 2018

What is the difference between bolts, screws and studs? Screw fastener clever identification

Aug 17, 2018

NAVIGATION

+86 755 8425 3369

+86 755 8467 6507

Block 4&Block 14, Beiguang Industrial Zone, No. 269 LiangBai Road, PingHu, Long Gang, Shenzhen, Guangdong, China.

FOLLOW US

Copyright © Shenzhen Manjun Precision Technology Co.,Ltd.

All Rights Reserved | Sitemap Technical Support: